Threshold, Door, Meet New Floor

This is just a dumb ole' technical post (and a retro one at that) being we have done little more than domesticate our home since the "move in". However, I have aquired the tools and materials to pimp our front door, as I had alluded to earlier. On that note, we have opted for the beveled glass inserts rather than an obscurred artglass filler, and props go to the homies what gave up the good advice, merideth & davidlbc. After looking in the local gaziers for the proper inserts (1/4" thick glass w/ a fat bevel), I realized the price was too puffy for me. Instead I found a stained/lead glass supplier who was able to get them to me for ~$1.50 ea. Not as thick nor fat as I'd hoped for, but adequate and a steal at that. That will be my task for this weekend.

Now,since we are already in the foyer, I should like to point out to you the incident that brought me to the above circumstance. It was the last day I would work on the house prior to our occupying it, and the task was for me to complete the flooring in the foyer. This meant a number of peripheral issues needing to be addressed:

- flashing where the flooring met the outdoors (this is about waterproofing)

- reseat the threshold (now 3/4" higher)

- cut off 1/2" from the bottom of the door

- remount the door (actually 1/4" higher, but not because of the floor)

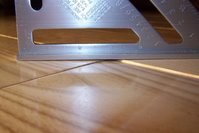

Here you see the nastiness that was before. This is only a gratuitous shot; not much to say here. We (parental supports & I) proceeded to lay the flooring up to and just beyond the first door jamb you see on the right of the picture. I chose to keep the existing oak threshold (at least for the time being) so we ran the floorboards to ~3/4" beyond the interior edge of threshold. As you may realize, the endgrain of a board more easily soaks up water/moisture than does the edge (think about grain like a tight bundle of tiny straws), and leaving the endgrain facing outside spells disaster. For this reason, one must place a terminal cap board perpendicularly and span the opening rather snuggly. I had a 1/16" clearance where this cap met either jamb (for eventual expansion). I won't bore you futher with calculations involving the coefficients for ash and the wet/dry bulb temperatures of the region.

Here you see the nastiness that was before. This is only a gratuitous shot; not much to say here. We (parental supports & I) proceeded to lay the flooring up to and just beyond the first door jamb you see on the right of the picture. I chose to keep the existing oak threshold (at least for the time being) so we ran the floorboards to ~3/4" beyond the interior edge of threshold. As you may realize, the endgrain of a board more easily soaks up water/moisture than does the edge (think about grain like a tight bundle of tiny straws), and leaving the endgrain facing outside spells disaster. For this reason, one must place a terminal cap board perpendicularly and span the opening rather snuggly. I had a 1/16" clearance where this cap met either jamb (for eventual expansion). I won't bore you futher with calculations involving the coefficients for ash and the wet/dry bulb temperatures of the region. After I got the first floorboard past the jamb (to establish the lay-line), I trimmed the cap you see here to a width just shy (3/4") of the exterior edge of the oak threshold (not shown). I will explain the reason for this gap later. I also need to point out a curiosity of this (and perhaps many ~100 year old) house(s). The (original d-f) flooring does not sit on top of the (original d-f) foundation. Again, the (o) floorboards stop just shy of the wall studs, and this meant that the (o) threshold that you see here was separate from it and there was a 1/4" gap that I really don't know how it was covered. We don't build like this these days.

After I got the first floorboard past the jamb (to establish the lay-line), I trimmed the cap you see here to a width just shy (3/4") of the exterior edge of the oak threshold (not shown). I will explain the reason for this gap later. I also need to point out a curiosity of this (and perhaps many ~100 year old) house(s). The (original d-f) flooring does not sit on top of the (original d-f) foundation. Again, the (o) floorboards stop just shy of the wall studs, and this meant that the (o) threshold that you see here was separate from it and there was a 1/4" gap that I really don't know how it was covered. We don't build like this these days.Instead, you lay the floor joists on the foundation & sill plate, and sheathe that with a sub-floor (typically 3/4" plywood). You then start your wall framing on top of this tabula rasa, threshold included. Well, not so here for some reason. And a garage is the same way. The interior concrete slabs are poured up to the foundation walls (rather than with the foundation). This may account for it being horrifically fractured and fissioned. Some day....

Anyways the consequence of that was that the top of the (o) threshold was higher than the top of the (o) flooring. I had to plane down the new end cap ~1/4+" to make it lock with the tongue ends and make for a flat finished surface. Fuss-fuss-fuss. I then fastened it down with wood screws and a fat bead of liquid nails, flashed the edge with a bit of handy-dandy all-purpose Z-bar (as shown), more liquid nails and screws, and voila! We are waterproofed! The (not-exactly orginal) oak threashold goes atop this, and a nice water-resistant wood trim piece (like teak) will go under that and cover the face of the Z-bar.

Anyways the consequence of that was that the top of the (o) threshold was higher than the top of the (o) flooring. I had to plane down the new end cap ~1/4+" to make it lock with the tongue ends and make for a flat finished surface. Fuss-fuss-fuss. I then fastened it down with wood screws and a fat bead of liquid nails, flashed the edge with a bit of handy-dandy all-purpose Z-bar (as shown), more liquid nails and screws, and voila! We are waterproofed! The (not-exactly orginal) oak threashold goes atop this, and a nice water-resistant wood trim piece (like teak) will go under that and cover the face of the Z-bar.Next up was the door. The initial problem was the door was mounted so there was a gap in excess of 1/4" at the top. This is something you can stick your finger through, or watch heated air escape from on a cold night. We took the door off its hinges, epoxied the screw holes on the jamb, and waited for it to cure. Next the hinge mortises had to be re-mortised to allow for the reseating of the hinges. A nice sharp chisel works great for this. After planing/sanding off the remaining excess off the door to make it fit (which was actually less than 1/4") we re-hung the door. This actually took 3 times to get the fit just right, and it was on that last re-mounting that I broke the window

getting it off the sawhorse. That was 5 weeks ago now that I have been staring at a taped up window every day....And I imagine changing these mini-panes are not going to be much easier than this was. We will see by my next post, unless I am electrocuted by my re-wiring fix-up first.

getting it off the sawhorse. That was 5 weeks ago now that I have been staring at a taped up window every day....And I imagine changing these mini-panes are not going to be much easier than this was. We will see by my next post, unless I am electrocuted by my re-wiring fix-up first.Labels: flooring, hardwood, threshold, waterproofing